What is insulator in HVAC? | FUNAS Guide

This article clarifies the function of insulators in HVAC systems. Understanding insulation is vital for optimizing energy efficiency, preventing condensation, and extending the lifespan of your equipment. We'll explore various insulator types and their applications, helping HVAC professionals troubleshoot and improve system performance.

What is an Insulator in HVAC? FUNAS

HVAC systems rely heavily on proper insulation to function efficiently and reliably. Poor insulation leads to energy waste, increased operating costs, and potential equipment damage. This article aims to demystify the role of HVAC insulators, focusing on their types, applications, and importance.

Types of HVAC Insulators

Several materials serve as effective insulators in HVAC applications. The choice depends on factors like temperature, application location, and cost. Common types include:

Fiberglass: A cost-effective and widely used insulator, offering good thermal performance. It's readily available in various forms, including blankets, rolls, and sleeves.

Mineral Wool: This inorganic material provides superior thermal and acoustic insulation compared to fiberglass, making it ideal for high-temperature applications or noise reduction.

Cellular Glass: Excellent for high-temperature applications and demanding environments due to its exceptional durability and resistance to moisture.

Polyisocyanurate (Polyiso): Known for its high R-value (a measure of thermal resistance), making it a preferred choice for reducing heat transfer in ductwork and other components.

Closed-Cell Spray Foam: This versatile insulator offers excellent air sealing and thermal performance, adaptable to various shapes and sizes. It's often chosen for retrofitting and new constructions.

The Importance of Proper Insulation

Effective insulation in HVAC systems offers numerous benefits:

Energy Efficiency: Reducing heat loss or gain significantly improves system efficiency, leading to lower energy bills.

Condensation Prevention: Proper insulation prevents condensation build-up, reducing the risk of corrosion and mold growth.

Improved Comfort: Insulated systems maintain more consistent temperatures, improving indoor comfort levels.

Extended Equipment Lifespan: Reduced stress on the system from temperature fluctuations extends the lifespan of components.

Noise Reduction: Some insulators, such as mineral wool, also help reduce noise generated by the HVAC system.

Selecting the Right Insulator

Choosing the right insulator requires considering the specific application and its environment. Factors to account for include:

Temperature Range: The material’s ability to withstand the operating temperatures of the system.

Moisture Resistance: Protecting against moisture intrusion is crucial for many applications.

Fire Resistance: Safety standards often require specific fire-resistance ratings for HVAC insulation.

Installation Ease: The ease of application can impact overall installation costs and time.

Cost-Effectiveness: Balancing thermal performance with the initial material cost is important.

By understanding the various types of HVAC insulators and their applications, professionals can optimize system performance, improve energy efficiency, and ensure the longevity of their HVAC equipment. Contact FUNAS for further assistance and expert advice.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

FAQ

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

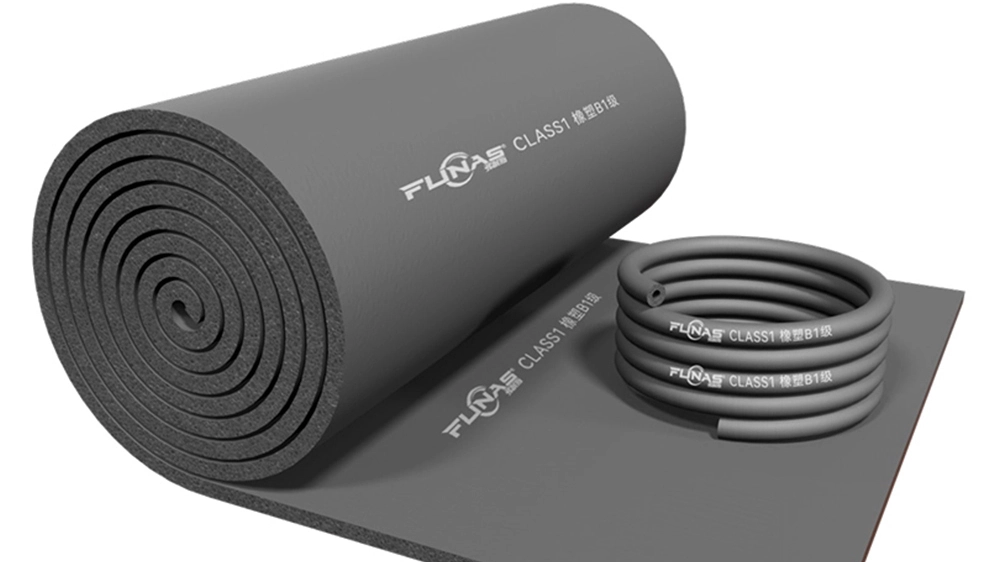

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

service

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.