What material commonly used for both ventilation and air conditioning ductworks? | FUNAS Guide

This article examines common materials used in ventilation and air conditioning ductwork, focusing on galvanized steel, aluminum, flexible ducting, and other options. It explores the advantages and disadvantages of each, guiding professionals towards informed material selection for optimal HVAC system efficiency and longevity. Choosing the right material impacts performance and cost; consider factors like budget, application, and environment.

What Material is Commonly Used for Both Ventilation and Air Conditioning Ductwork?

Choosing the right material for your HVAC ductwork is crucial for efficiency and longevity. This article clarifies common materials used for both ventilation and air conditioning systems, helping you make informed decisions. Understanding the properties of each material will help avoid costly mistakes and ensure optimal system performance.

Galvanized Steel: The Industry Standard

Galvanized steel remains the most prevalent material for both ventilation and air conditioning ductwork. Its strength, durability, and resistance to corrosion make it ideal for a wide range of applications. The zinc coating protects against rust, extending the lifespan of the ductwork, especially important in environments with high humidity. While more expensive than some alternatives, its robust nature and longevity often make it the most cost-effective choice in the long run.

Aluminum: Lightweight and Versatile

Aluminum ductwork offers a lighter-weight alternative to steel, simplifying installation and reducing structural load. It’s also highly resistant to corrosion, making it suitable for various environments. However, aluminum is less robust than galvanized steel and can be susceptible to damage during handling and installation. It’s often preferred in applications where weight is a major consideration or where corrosion resistance is paramount. For air conditioning systems, its reflective properties can contribute to slightly improved energy efficiency.

Flexible Ducting: For Specific Applications

Flexible ducting, typically made of galvanized steel or aluminum foil with a plastic liner, is utilized in situations where rigid ductwork is impractical. Often used for short runs, connecting to individual outlets or in areas with limited space, flexible ducting provides flexibility and ease of installation. However, it's generally less efficient than rigid ductwork due to increased air friction and is therefore not typically recommended for large-scale projects.

Other Materials: Fiberglass and PVC

While less common for main ductwork, materials like fiberglass and PVC are sometimes used in specific applications. Fiberglass ductwork is lightweight and offers good insulation properties, but its rigidity and susceptibility to damage limit its use. PVC is suitable for low-pressure applications and is resistant to corrosion, but its limited temperature tolerance restricts its suitability for certain HVAC systems.

Choosing the Right Material:

The optimal material choice depends on several factors, including budget, application, environmental conditions, and project specifics. Consulting with experienced HVAC professionals is crucial to ensure the right material selection for your unique needs.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

service

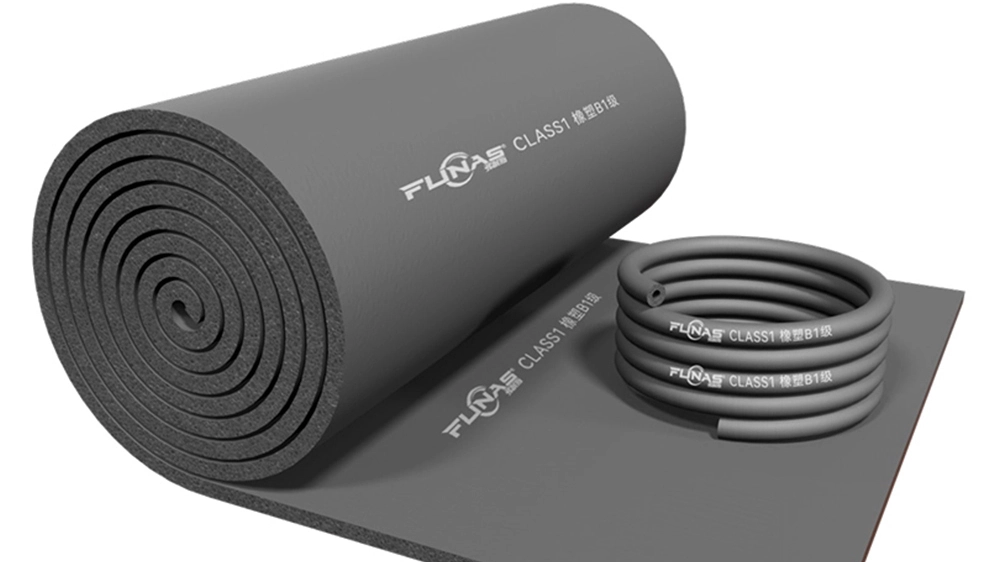

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

Can I request custom dimensions or properties for my insulation needs?

Yes, we specialize in custom solutions. Whether you need specific dimensions, thicknesses, densities, or additional coatings, we can work with you to manufacture insulation products tailored to your exact requirements of good materials for heat insulation.

FAQ

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

How to start a consultation?

You can contact us through our website, phone, or email. We will arrange a professional staff to discuss your needs about best thermal insulator and how we can help you.

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.