What are the disadvantages of thermal insulation? | FUNAS Guide

Thermal insulation, while beneficial, has drawbacks. Higher initial costs and potential for moisture problems are key concerns. Material limitations, installation difficulties, and space consumption also need consideration. Choosing the right insulation requires weighing these disadvantages against its energy-saving benefits. FUNAS helps professionals navigate these choices.

What are the Disadvantages of Thermal Insulation?

While thermal insulation offers significant advantages in energy efficiency and comfort, it's crucial to understand its potential drawbacks. This article explores the disadvantages of thermal insulation, helping professionals make informed decisions in building design and construction. Ignoring these downsides can lead to costly mistakes and performance issues.

Increased Initial Costs

One of the most prominent disadvantages is the higher upfront cost. Investing in high-quality thermal insulation materials and skilled installation significantly increases the initial project budget. This can be a major hurdle, particularly in projects with tight financial constraints.

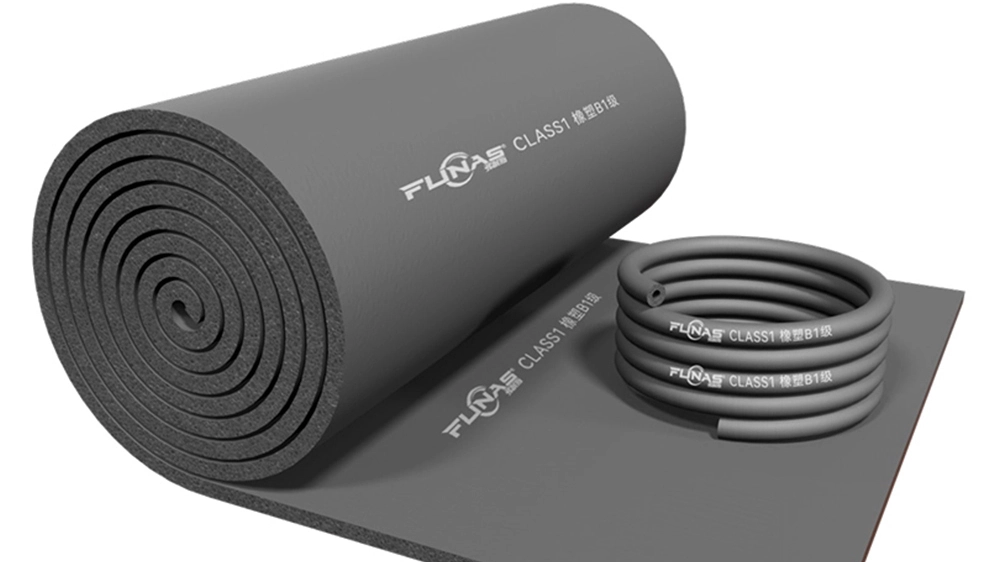

Material Limitations and Degradation

Different thermal insulation materials have specific limitations. Some are susceptible to moisture damage, reducing their effectiveness over time. Others may have limited durability or require specialized handling, adding complexity to the installation process. Proper material selection, considering the specific application and environmental conditions, is crucial to mitigate these issues.

Installation Challenges

Installing thermal insulation can be labor-intensive and challenging, especially in complex building designs. Proper installation is crucial for optimal performance; inadequate installation can lead to voids and thermal bridging, negating the benefits of the insulation itself. Specialized skills and tools are often required for proper installation, further increasing costs.

Potential for Increased Moisture Problems

Improperly installed thermal insulation can trap moisture, leading to mold growth, rot, and other structural damage. This is particularly true for materials that absorb moisture. Effective vapor barriers and appropriate ventilation strategies are essential to prevent these problems, especially in cold climates.

Reduced Air Circulation

Some types of thermal insulation can impede airflow, potentially affecting indoor air quality. Careful consideration should be given to ventilation strategies to ensure adequate air circulation and to mitigate the risk of stuffiness or the buildup of pollutants.

Environmental Impacts

While insulation improves energy efficiency, the production and transportation of some insulation materials have environmental impacts. Consider the embodied energy and carbon footprint of different materials when making your choices. Focusing on sustainable and recycled materials can help to lessen the environmental burden.

Space Consumption

Insulation materials occupy space within building structures. This can be a significant factor in projects with limited space, potentially affecting the usable area of buildings or requiring design modifications to accommodate the insulation.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

FAQ

How to start a consultation?

You can contact us through our website, phone, or email. We will arrange a professional staff to discuss your needs about best thermal insulator and how we can help you.

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

service

Can I request custom dimensions or properties for my insulation needs?

Yes, we specialize in custom solutions. Whether you need specific dimensions, thicknesses, densities, or additional coatings, we can work with you to manufacture insulation products tailored to your exact requirements of good materials for heat insulation.

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.