How much does acousticfoam reduce sound? | FUNAS Guide

Discover how acoustic foam impacts noise levels. This guide explains sound absorption coefficients (α), crucial factors (foam thickness, density, material, installation), and limitations. Achieving significant sound reduction often requires combined solutions with acoustic foam as one component. Learn how to choose the right solution for your application. Trust FUNAS for expert acoustic solutions.

How Much Does Acoustic Foam Reduce Sound? FUNAS

Determining how much acoustic foam reduces sound is crucial for professionals seeking effective noise control. Understanding the factors influencing sound absorption is key to selecting the right solution for your specific application. This article clarifies the complexities of acoustic foam performance and its impact on sound levels.

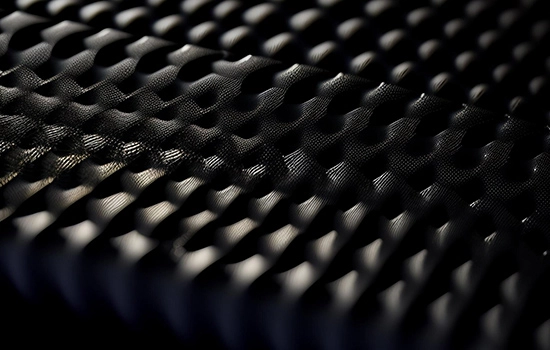

Understanding Sound Absorption Coefficients

Acoustic foam's effectiveness is measured by its sound absorption coefficient (α). This coefficient, ranging from 0 (no absorption) to 1 (complete absorption), indicates the percentage of sound energy absorbed at a specific frequency. A higher α value signifies better sound absorption. Note that this coefficient is frequency-dependent; foam performs differently at different sound frequencies.

Factors Affecting Sound Reduction with Acoustic Foam

Several factors significantly influence the overall sound reduction achieved with acoustic foam:

* Foam Thickness: Thicker acoustic foam generally absorbs more sound energy, particularly at lower frequencies. Thinner foam is more effective at higher frequencies.

* Foam Density: Denser foam typically offers superior sound absorption. However, density impacts cost and may not always be the most practical solution.

* Foam Material: Different materials offer varying absorption capabilities. For example, polyurethane foam is common, but other materials, like melamine foam, may provide better performance in certain situations.

* Installation Method: Proper installation is critical. Gaps between foam panels can drastically reduce effectiveness.

* Room Geometry and Size: The room's size and shape influence sound reflection and reverberation, impacting overall acoustic performance. More complex room shapes require more extensive treatment.

* Sound Source and Frequency: The nature of the sound source (e.g., machinery, conversation) and its frequency content significantly affect the effectiveness of acoustic foam treatment.

Practical Implications and Considerations

Acoustic foam rarely provides complete soundproofing. It's primarily designed to control reverberation and reduce unwanted echoes within a space. For significant noise reduction, other soundproofing methods like double glazing, sound-dampening walls, and barrier materials are often necessary in conjunction with acoustic foam.

While acoustic foam is cost-effective for many applications, the selection process requires careful consideration of its absorption coefficient, thickness, density, and the specific acoustic challenges in your project. Don't hesitate to consult with acoustic experts for complex or critical applications. Accurate sound measurements are vital for determining the necessary level of treatment.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

service

What is your shipping and delivery process like?

We offer reliable logistics services for insulation material wholesale, both domestically and internationally. Our team ensures secure packaging, timely shipping, and real-time tracking so that your order reaches you in perfect condition and on schedule.

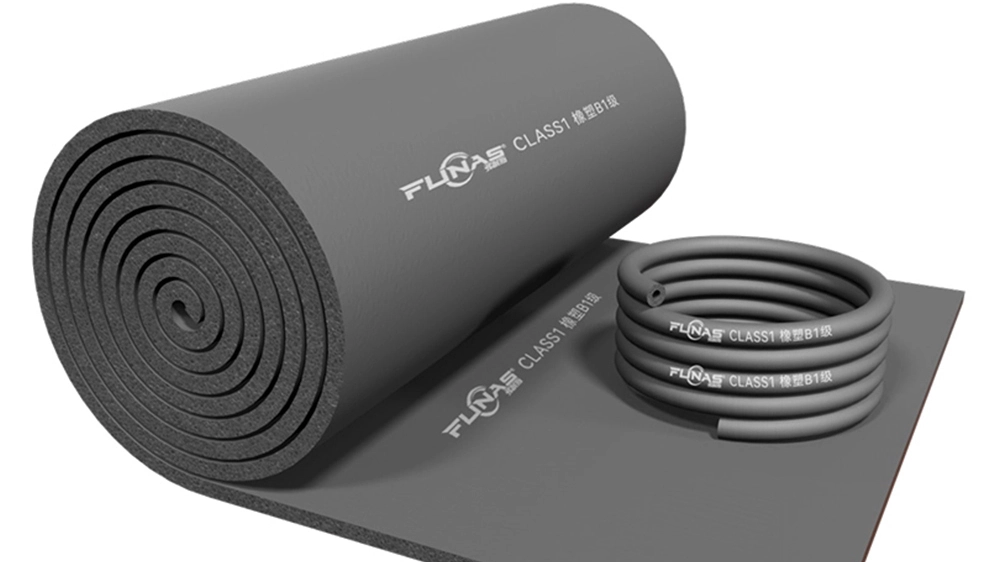

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

Can I request custom dimensions or properties for my insulation needs?

Yes, we specialize in custom solutions. Whether you need specific dimensions, thicknesses, densities, or additional coatings, we can work with you to manufacture insulation products tailored to your exact requirements of good materials for heat insulation.

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

FAQ

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.