What are the disadvantages of polyurethane foam? | FUNAS Guide

Polyurethane foam, despite its popularity, presents disadvantages including VOC emissions, moisture sensitivity, fire hazards, application challenges, and long-term degradation. Understanding these limitations is crucial for selecting the best insulation solution. Consider low-VOC options and proper installation to mitigate some drawbacks. FUNAS provides expert insulation solutions.

What are the Disadvantages of Polyurethane Foam?

Polyurethane foam, while a popular thermal insulation material, presents certain drawbacks that professionals in the field should consider. This article outlines key disadvantages, helping you make informed decisions for your insulation projects. Understanding these limitations is crucial for selecting the optimal material for specific applications.

Health and Environmental Concerns

One significant disadvantage is the potential release of harmful volatile organic compounds (VOCs) during and after polyurethane foam installation. These VOCs can contribute to poor indoor air quality and pose health risks. Furthermore, the manufacturing process and disposal of polyurethane foam have environmental implications, impacting sustainability efforts. Choosing low-VOC or bio-based polyurethane options can mitigate some of these issues.

Moisture Sensitivity

Polyurethane foam is susceptible to moisture absorption, which can significantly reduce its thermal performance. Water intrusion, even in small amounts, can lead to degradation and a loss of R-value over time. Proper installation techniques and the use of vapor barriers are essential to prevent this. Water damage can also foster mold growth, adding to the health concerns mentioned previously.

Fire Hazards

While many polyurethane foam formulations include fire retardants, they remain combustible materials. Proper fire safety precautions are vital during installation and throughout the lifespan of the insulation. Understanding the specific fire-resistance rating of the chosen polyurethane foam is critical for compliance and safety.

Application Challenges

Spray polyurethane foam (SPF) applications, in particular, require specialized equipment and skilled technicians. Inconsistent application can lead to uneven insulation, compromising thermal performance and potentially creating weak points. The expanding nature of the foam during application also necessitates careful planning to avoid damage to surrounding structures.

Durability and Aging

Like many materials, polyurethane foam degrades over time, though the rate varies depending on the formulation and environmental factors. UV exposure, especially in exposed applications, can accelerate the degradation process. The long-term performance of polyurethane foam should be carefully considered for projects requiring extended durability.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

service

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

Can I request custom dimensions or properties for my insulation needs?

Yes, we specialize in custom solutions. Whether you need specific dimensions, thicknesses, densities, or additional coatings, we can work with you to manufacture insulation products tailored to your exact requirements of good materials for heat insulation.

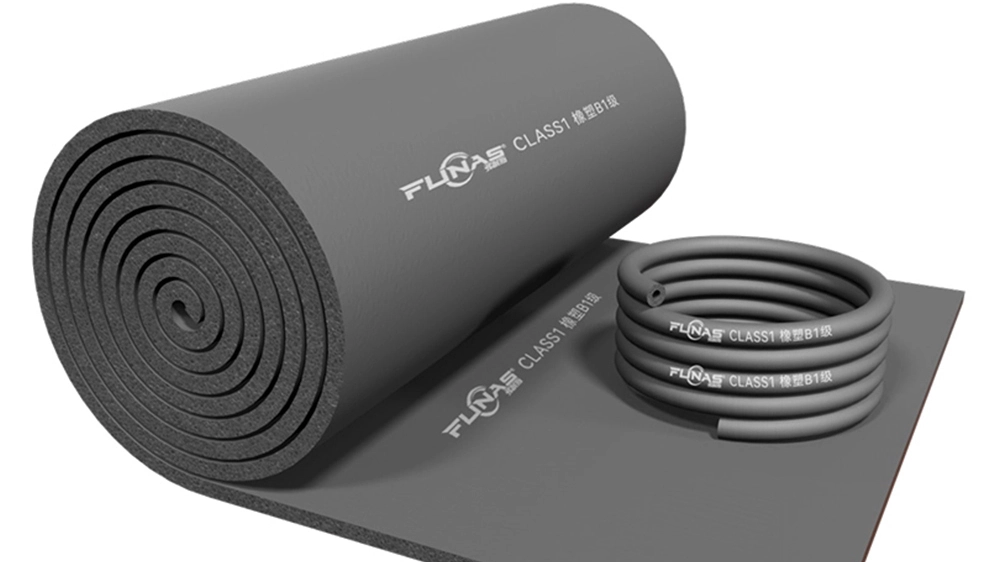

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

FAQ

How to start a consultation?

You can contact us through our website, phone, or email. We will arrange a professional staff to discuss your needs about best thermal insulator and how we can help you.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.