Is 100% thermal insulation possible? | FUNAS Guide

100% thermal insulation is theoretically impossible due to thermodynamics. This article explores heat transfer mechanisms (conduction, convection, radiation) and practical approaches to maximize insulation using materials like VIPs and MLI, pushing the boundaries of thermal performance. FUNAS.

Is 100% Thermal Insulation Possible?

Many professionals in the thermal insulation materials industry grapple with the limitations of achieving perfect insulation. This article explores the theoretical ideal of 100% thermal insulation and the practical realities of minimizing heat transfer. We'll examine why complete elimination of heat flow is impossible and discuss strategies for maximizing thermal insulation performance.

The Thermodynamics of Heat Transfer

The fundamental principles of thermodynamics dictate that heat transfer will always occur unless a temperature difference is nonexistent. Heat transfer happens via three primary mechanisms: conduction, convection, and radiation. Even the most advanced thermal insulation materials only *reduce* heat transfer, they cannot completely stop it. Eliminating all three mechanisms simultaneously is physically impossible.

Conduction Limitations

Materials with low thermal conductivity, such as aerogels or vacuum insulation panels, significantly impede conductive heat transfer. However, some level of conduction will always remain at a microscopic level. The movement of phonons (vibrational energy) within the material's structure ensures some heat flow. Improving thermal insulation involves selecting materials with the lowest possible thermal conductivity, and minimizing pathways for heat flow.

Convection and Radiation Challenges

Convection currents in air or liquids trapped within an insulating layer will transfer heat, albeit inefficiently, even with extremely low permeability materials. Radiation, the electromagnetic transfer of heat, is even harder to mitigate completely. Multi-layered insulation with reflective surfaces minimizes radiation, but some heat transfer through radiation will always occur.

Practical Approaches to Near-Perfect Insulation

While 100% thermal insulation is a theoretical impossibility, achieving near-perfect insulation for specific applications is possible through careful material selection and design. This involves:

* Optimizing material properties: Selecting materials with exceptionally low thermal conductivity, high reflectivity, and low permeability.

* Minimizing air gaps and voids: Ensuring a dense and continuous insulation layer prevents convective heat transfer.

* Utilizing vacuum insulation panels (VIPs): VIPs offer superior performance by removing air and significantly reducing both conduction and convection.

* Employing multi-layer insulation (MLI): MLI uses multiple layers of reflective material to minimize radiative heat transfer.

Conclusion

The pursuit of 100% thermal insulation is a valuable goal driving innovation in the industry. Although complete heat transfer elimination is unattainable, significant advancements in material science and insulation design constantly push the boundaries of thermal performance. By understanding the limitations and employing optimal strategies, professionals can achieve remarkable levels of thermal insulation and meet the demands of demanding applications.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

service

How does your technical support work?

Our technical support team is available to guide you through every stage of your project—from product selection and design to installation. We provide expert consultation to ensure that you get the best insulation solution for your needs and can assist with troubleshooting if needed.

FAQ

How to start a consultation?

You can contact us through our website, phone, or email. We will arrange a professional staff to discuss your needs about best thermal insulator and how we can help you.

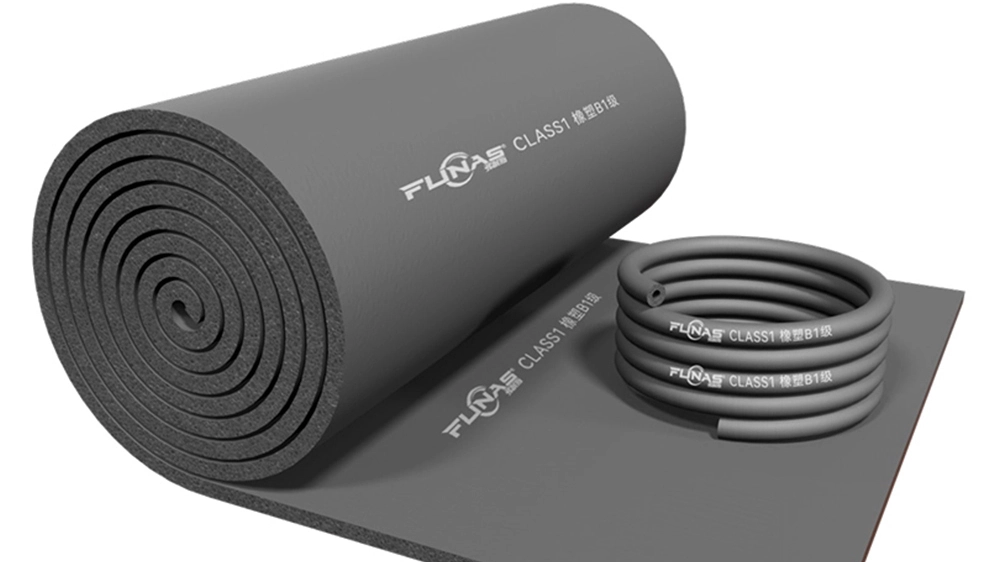

What types of rubber foam insulation do you offer?

We offer a wide range of rubber foam insulation with different thicknesses and specifications. Thermal insulation material manufacturer FUNAS sleeves and sheets are suitable for different application scenarios.

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

What is the typical delivery time for custom orders?

Our daily production capacity is 800 cubic meters. Delivery time varies depending on the complexity of the insulation material wholesale order, but we can deliver large quantities of customized products within 4-6 weeks after the approval date, and small quantities can be delivered within 15 days.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.