What are the insulationclasses? | FUNAS Guide

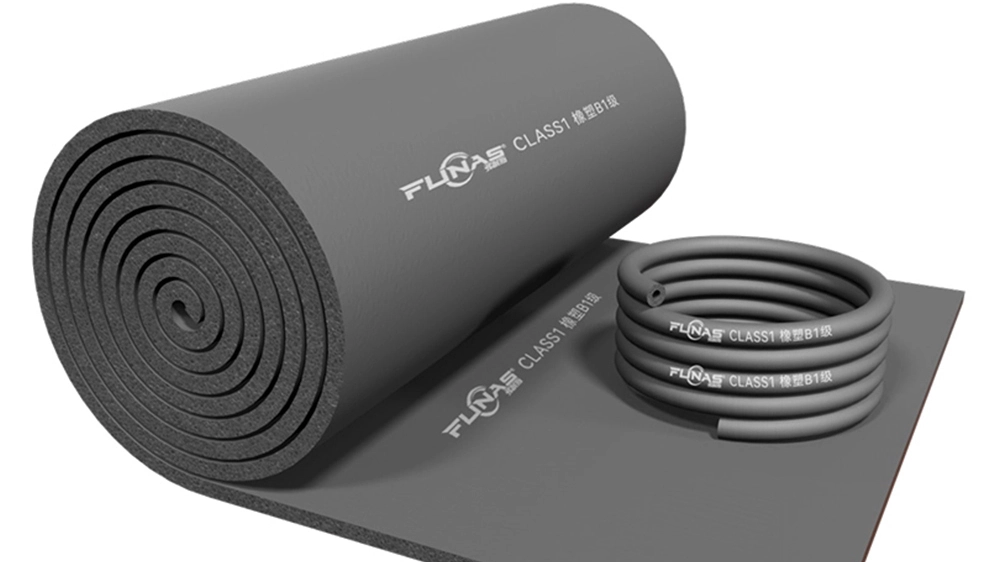

This article clarifies thermal insulation material classifications, covering thermal conductivity, fire resistance, and application-specific categories. Understand the importance of selecting the correct class for optimal performance and safety. FUNAS helps you find the right solution.

What are the Insulation Classes?

Understanding insulation classes is crucial for selecting the right thermal insulation materials for your project. This article clarifies the different classification systems and their implications, helping you avoid common pitfalls and ensure optimal performance. Choosing the wrong insulation can lead to wasted energy, increased costs, and compromised safety.

Classification Systems for Thermal Insulation Materials

Several systems classify thermal insulation materials, each focusing on different properties. These systems aren't always interchangeable, so understanding the nuances is vital. Key factors include thermal conductivity, fire resistance, and application-specific requirements.

Thermal Conductivity Classification

This is perhaps the most common method, focusing on the material's ability to conduct heat. Lower values indicate better insulation. Often expressed as λ (lambda) in W/m·K, this value dictates the material's R-value (thermal resistance) which is critical for calculating heat loss or gain in building design and energy efficiency assessments. Different standards might use slightly different testing methods, leading to minor variations in reported values.

Fire Resistance Classification

Fire safety is paramount. Insulation materials are classified according to their reaction to fire, often using standards like Euroclasses (A1, A2, B, C, D, E, F) or similar national systems. These classifications detail how a material will behave when exposed to flames, from non-combustible (A1) to highly flammable (F). The choice greatly depends on the application, with stricter requirements for buildings or industrial settings. Always check local building codes and regulations.

Application-Specific Classifications

Beyond general thermal and fire properties, insulation materials are often categorized by their intended application. For instance, pipe insulation, industrial insulation, or HVAC insulation each has specific performance and physical property requirements. This includes factors like temperature resistance, moisture resistance, and mechanical strength. The specific requirements vary depending on the particular application and environmental conditions.

Selecting the Right Insulation Class

Choosing the appropriate insulation class requires careful consideration of all relevant factors. Consulting material datasheets, understanding local codes, and seeking expert advice ensures optimal performance, safety, and compliance with regulations. Remember to always consider the long-term implications of your selection, factoring in maintenance, longevity and environmental impact.

Best Car Sound Insulation Material Suppliers List

10 Best Industrial Rubber Sheet Manufacturers

How to Insulate Pipes in Attic: Easy Steps for Energy Efficiency

2025 Tips: What is the Best Insulation for Pex Pipe

How to Insulate Pipes: Effective Solutions for Long-Term Protection

FAQ

What is the typical delivery time for custom orders?

Our daily production capacity is 800 cubic meters. Delivery time varies depending on the complexity of the insulation material wholesale order, but we can deliver large quantities of customized products within 4-6 weeks after the approval date, and small quantities can be delivered within 15 days.

Can your insulation products be customized?

Yes, we offer customized solutions for insulation material wholesale to meet the specifications of your project, including custom specifications, sizes, foils and adhesives, colors, etc.

How do I choose the right insulation for my project?

Our team can help you choose the best material for heat insulation based on your specific needs, such as thermal resistance, acoustic properties, and environmental conditions.

service

Are your rubber foam products environmentally friendly?

Yes, our insulation products are designed with sustainability in mind. They help reduce energy consumption by minimizing heat loss and gain, and they are made from durable materials that have a long life cycle, reducing the need for frequent replacement.

What types of rubber foam insulation products do you offer?

We offer a wide range of rubber foam insulation products, including custom shapes and sizes, thermal and acoustic insulation solutions, and options with specialized coatings such as flame retardancy and water resistance. Our products are suitable for applications in HVAC, automotive, construction, and more.

You might also like

This product has passed the national GB33372-2020 standard and GB18583-2008 standard. (The product is a yellow liquid.)

Anggu foam phenolic glue is a kind of glue with corrosion resistance, low odor, high strength and excellent brushing property. Can be sprayed for construction with fast surface drying speed, long bonding time, no chalking and convenient operation.

This product has passed the EU REACH non-toxic standard, ROHS non-toxic standard. (The product is black glue.)

Anggu 820glue is a low-odor, high-strength quick-drying glue; Fast drying speed, long bonding time, no powder, non-toxic.

Leave a message

Have any questions or concerns about our products? Please leave us a message here and our team will get back to you promptly.

Your queries, ideas, and collaboration opportunities are just a click away. Let’s start a conversation.